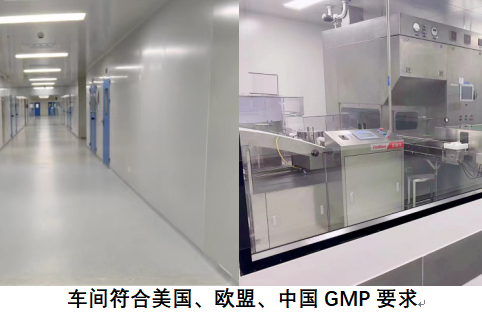

Zhejiang Poly Pharmaceuticals is a wholly-owned subsidiary of Hainan Poly Pharmaceutical (stock code: 300630). Its oral liquid production line was completed in 2022 and received domestic GMP production approval on March 31, 2023. The workshop was designed to international standards, and top-tier domestic and international equipment brands were selected. The key components of the compounding system and washing-filling-sealing integrated equipment are all imported brands, suitable for the production of both simple and complex formulations. The workshop complies with the GMP requirements of the United States, the European Union, and China, with an annual comprehensive production capacity of over 200 million bottles.

Compounding System Meets the Needs of Different Complex Processes

The compounding system can accommodate different batch sizes ranging from 250L to 3000L, catering to production needs at various stages, from research and development to commercialization.

The precise temperature control technology during the compounding process (±2°C), combined with a combination of tank-mounted paddle and magnetic stirring, allows for rapid and accurate achievement of process requirements, ensuring uniform stability of common solutions, syrups, and suspensions.

Equipped with a US-made Urschel comminuting machine (Comitrol 1500), it can meet the process requirements of viscous and suspended complex formulations using advanced international comminution technology.

Feeding is equipped with a solid-liquid dispersion system, using German processing technology, to reduce material clumping, agglomeration, and volatility during the wetting process, ensuring thorough dispersion, emulsification, homogenization, comminution, and blending of materials.

It has an automatic CIP (Clean-In-Place) system to meet the cleaning requirements of complex solutions with characteristics such as poor solubility and high viscosity.

Filling System Meets Various Single-Bottle Volume Production Needs

The fully automatic washing-drying-filling integrated system can meet the production needs of various materials, including glass and plastic bottles. Additionally, it is equipped with an automatic bottle arranging mechanism to meet the production requirements of non-washed plastic bottles.

The integrated line can meet filling requirements ranging from 30ml to 300ml per bottle, and the HGF rotary oral liquid filling machine can meet filling requirements from 1ml to 10ml per bottle. Currently, there are molds available for bottle sizes of 60ml, 125ml, 150ml, 300ml, and small capacity molds for 10ml.

The integrated line can achieve a single-bottle filling accuracy of ≤1.0%; the HGF rotary oral liquid filling machine can achieve a single-bottle filling accuracy of ≤1.5%; for syrups and suspensions, the single-bottle filling accuracy can reach ≤3%.

The high precision and advanced equipment and processes of Zhejiang Poly Pharmaceutical make it a competitive pharmaceutical manufacturer and partner. Its modern oral liquid production line not only complies with domestic GMP requirements but also meets the GMP requirements of the US and the EU, providing it with significant opportunities to expand into international markets.

Zhejiang Poly Pharmaceutical's compounding system has the production capacity for various processes, catering to the needs of different formulations, whether for research and development or commercial production. The precise temperature control and efficient compounding technology ensure the uniformity and stability of formulations, which are crucial for the quality of oral liquid formulations.

Furthermore, the filling system is highly flexible and can accommodate different bottle sizes, including glass and plastic bottles. This versatility enables it to meet the production requirements of various oral liquid products, providing more choices for customers.

Zhejiang Poly Pharmaceutical is very willing to cooperate with domestic and international partners to drive the development of the pharmaceutical industry. Its production capabilities conforming to international standards and rigorous quality control system make it a reliable partner for jointly developing new products, expanding market share, and delivering high-quality oral liquid formulations to patients. This will contribute to strengthening innovation and international competitiveness in the pharmaceutical industry, benefiting more patients and consumers.

-

[Previous]Poly Pharmaceuticals has successfully developed Ursodeoxycholic acid (UDCA) API and looks forward to exploring the global market together with you.

-